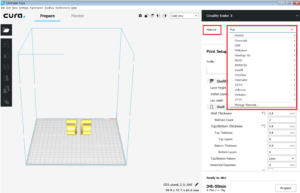

It’s important enable support if you have something that is suspended in the air.This is because at the beginning we want it to be as hot as possible to make good adhesion of the PLA to the plate. In this box is important that INITIAL FAN SPEED is set to 0.it’s very important use a low speed for first level ( INITIAL LAYER SPEED and INITIAL LAYER PRINT SPEED, this give to PLA the time to join well to the plate.In any case remember the low speed means optimum quality of print. Second try to print the same object with a different speeds until you find a good soluction.īelow there are our configuration for printing the CCTREE PLA 3D Stampante a Filamento – BIANCO Speed are very important because conditioning the final result of our printing.įirst look on internet your PLA or other filament that you use and see the comments of the users.Thanks to this option we avoid that printer release a filaments from one part to anoter one. We consider very important enable the RETRACTION DISTANCE and RETRACTION SPEED because thanks to this parameter the printer retract the PLA during a movement from one print area to another one.We use the CCTREE PLA 3D Stampante a Filamento – BIANCO, if you use another PLA see the data sheet of your PLA. The configuration below are for PLA but depend also of the PLA that you use. The parameters below, regarding the temperature, depends of the material that you use.INFILL DENSITY, it’s a percentage that you choose based on how dense you want your print.IRONING, we use this because is a good solution for hide or better connect two successive lines.TOP/BOTTOM THICKNESS, are the thickness that must be a multiple of the value set in the LAYER HEIGHT.WALL LINE COUNT, is automatic calculate in base of the WALL THICKNESS.WALL THICKNESS is the thickness of the wall, we suggest 0,8 mm but if you need a more robust construction increase this value.ĪTTENTION: in our case we had configure the LINE WIDTH at 0,4 mm (is the diameter of the CURA 3 nozzle) so the WALL THICKNESS must be an multiple of LINE WIDTH, 0,8 or 0,12 or 0,16, etc.LINE WIDTH is the diameter of the extruder, in CURA 3 is 0,4 mm.INITIAL LAYER HEIGHT is the first layer drawing by the 3D printer, we suggest to choose 0,2 mm for leave on the printer area, a good thickness of material (PLA in our case).LAYER HEIGHT for a standard 3D print select 0,15 mm, if you need more precision choose 0,1 mm or if you are hurry choose 0,2 mm.Now we must configure the options regarding the QUALITY, the SHELL, etc.īelow there is a global overview of all configurations.ĭon’t worry we will explain step by step all in this tutorial. Now is necessary choose the filament that you need to use, see below. M104 S F1000 Move Heat Bed to the front for easy print removal It’s also necessary configure the Start-G and the End-G code. It’s important to configure the dimension of the plate (Printer Setting) at: Select: SETTINGS → PRINTER → M A NAGE PRINTERS, see below.įrom the new page ADD a new printer, in our case ENDER 3, and next select: MACHINE SETTINGS.

I'll close this ticket since half of it is expected behaviour and the other half duplicates #6106.After start CURA (my version is: 3.5.1) you must configure a new printer, in our case is the ENDER 3, for do this follow the steps below. If you have any suggestions to improve them, I think you should post them here: #6106 These profiles are not maintained by Ultimaker though but by the community of Creality printer users. However the problem that Vashnevskaya seems to want to indicate is with the actual settings printing more towards quality than productivity than before. This can be amended by enabling Jerk and Acceleration control and further specifying the machine settings for max feedrate to match your firmware. The difference could be explained by Cura's defaults not matching up with your firmware's defaults for acceleration, jerk, maximum/minimum feedrates, etc. However for your Ender 3 I have no idea what fluctuations you get. Based on the value for this setting, Cura automatically calculates how fast to move the extruder motor for certain print speeds or filament diameters. This would be too much for Ultimaker's printers since we assume a 5% fluctuation in Marlin's stepper timing. Cura settings for Ender 3 and other Creality printers The extrusion multiplier, which is called flow rate in Ultimaker’s Cura, specifies the rate at which your printer will extrude material. Your test indicates a difference of 2h48 vs. If the time estimates of Cura match the actual printing time, there is nothing that Cura can improve in this regard.

0 kommentar(er)

0 kommentar(er)